Fixing my school's CNC router and saving $700

Background

My school had a broken Carvey. The Carvey is a (now discontinued) desktop CNC router made by Inventables. I convinced my school to not surplus it (effectively throwing it out) and let me try and fix it, and they agreed! I brought it home where it stayed for several months, until I finally had the time to fix it.

Diagnosis

Looking through the Inventables Community forum, I figured out what gcode to use to home individual axis and determined several problems. Someone at the school had attempted to replace the Y-axis stepper motor with a broken one, but thankfully they left the original stepper, which I reinstalled. This was really weird, I don’t know what that person was thinking. The other problem, much more serious, was that the Z-axis stepper was fried. When I tried to move the z-axis, the motor would budge slightly and let out a high pitched whine, but never rotate.

Finding Replacement Part

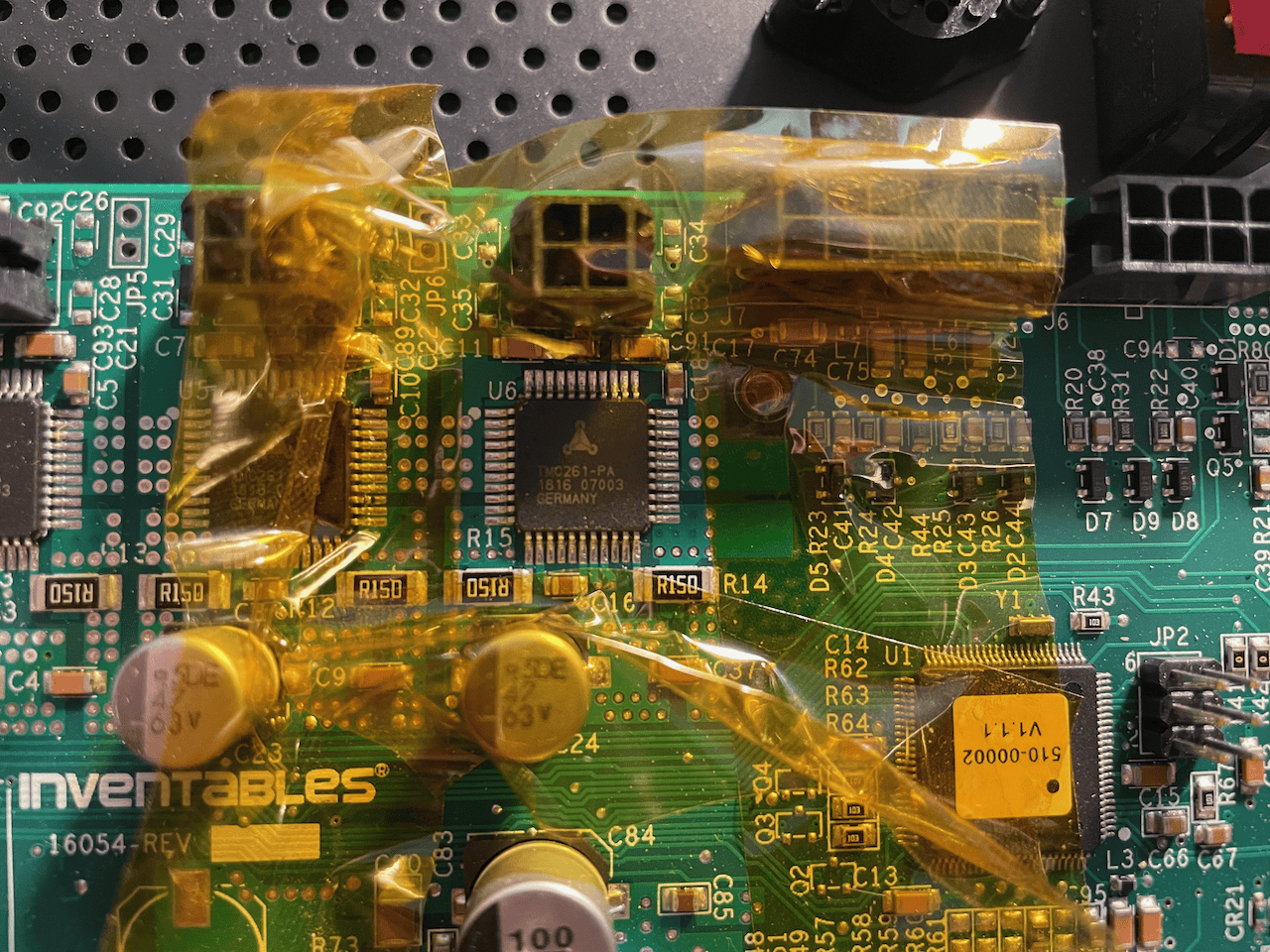

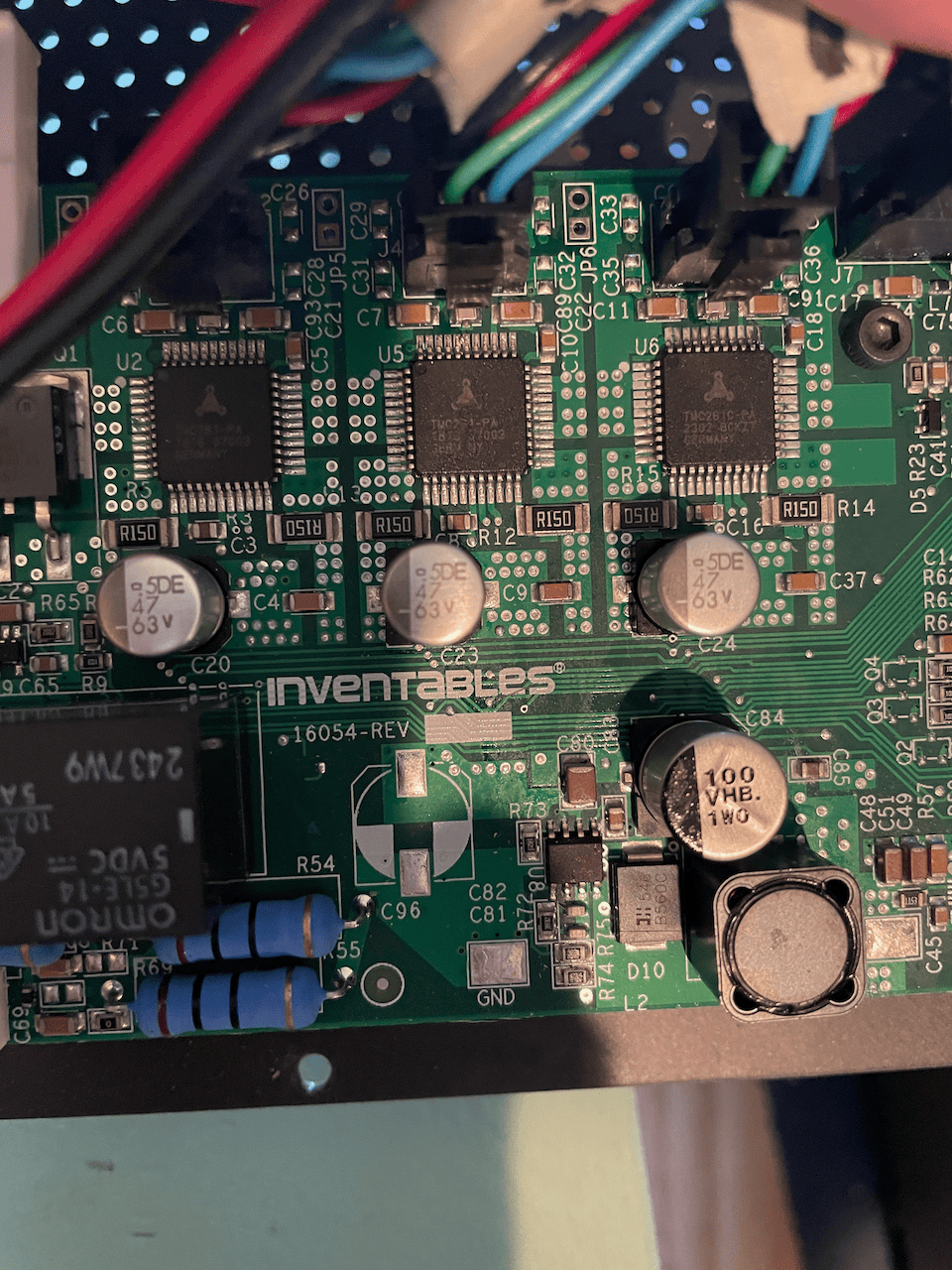

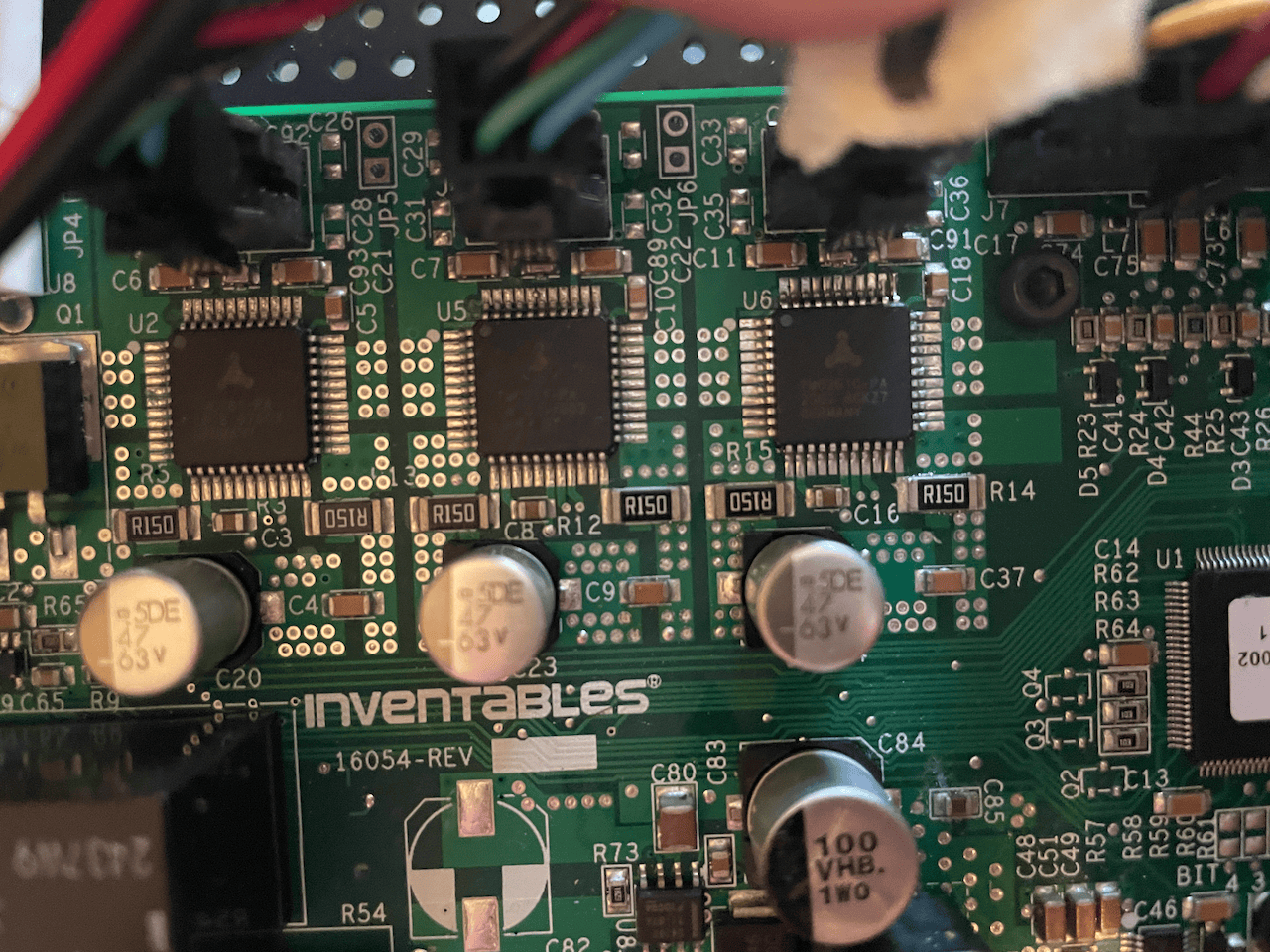

The Carvey (or at least the one we had) ships with TMC261-PA drivers, which were discontinued. However, while searching for a replacement, I found that Trinamic made a TMC261C-PA. This site told me that I could indeed replace the orignal with the new “c” variant. So I ordered the TMC261C-PA from digikey, for a total of $18.31 shipped.

Installing Replacement

This was only my second (and still is at the time of writing, 11/23) time repairing something with hot air soldering, so I was pretty nervous ngl. And I didn’t really know what I was doing (well I kinda did, but feel free to critique me).

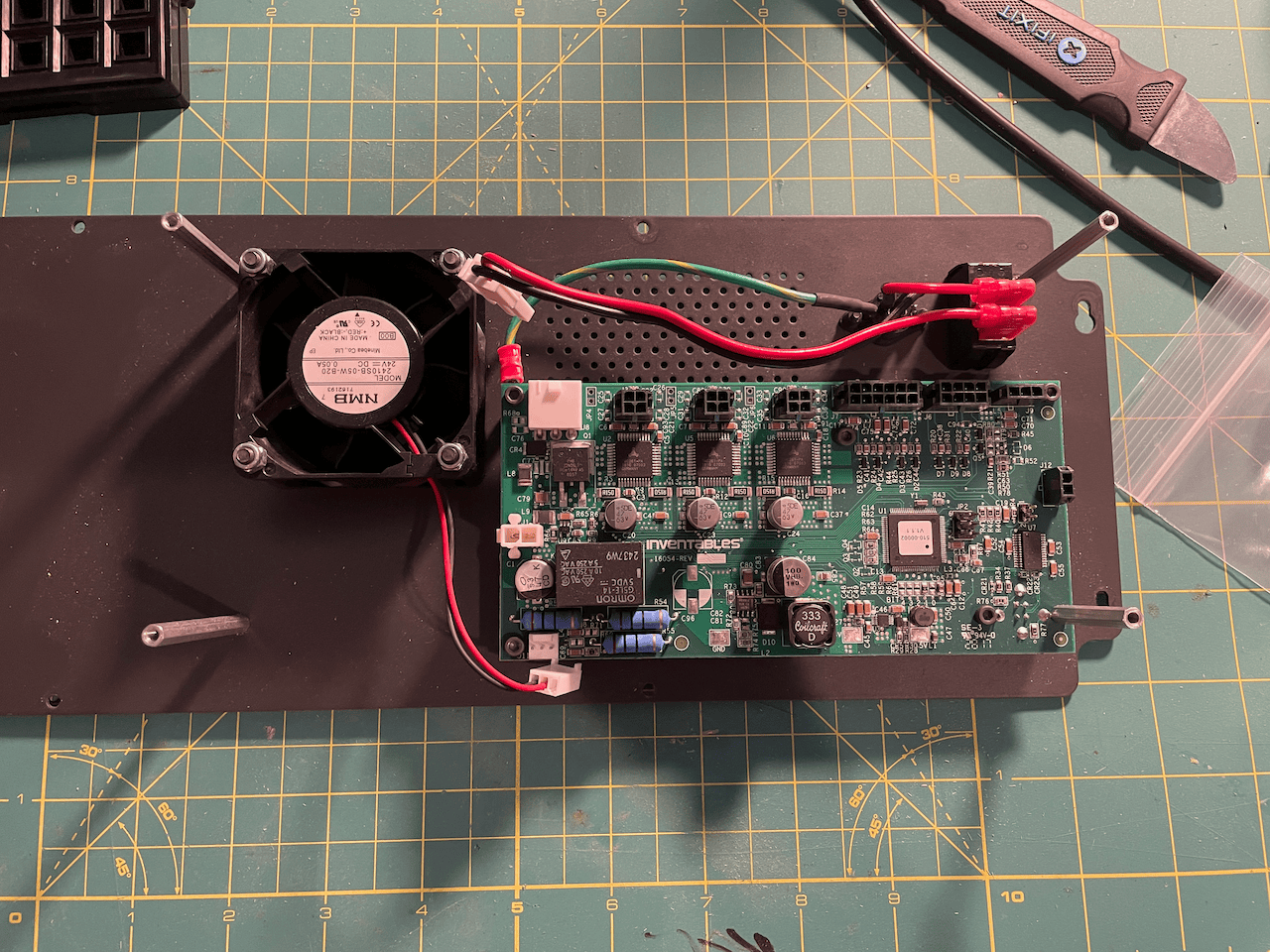

First I removed the back panel from the carvey. This was the part that Inventables was quoting $700 to replace, as they could not just send a mainboard. But even that would have probably still been expensive.

Then, I covered the surrounding area in kapton tape.

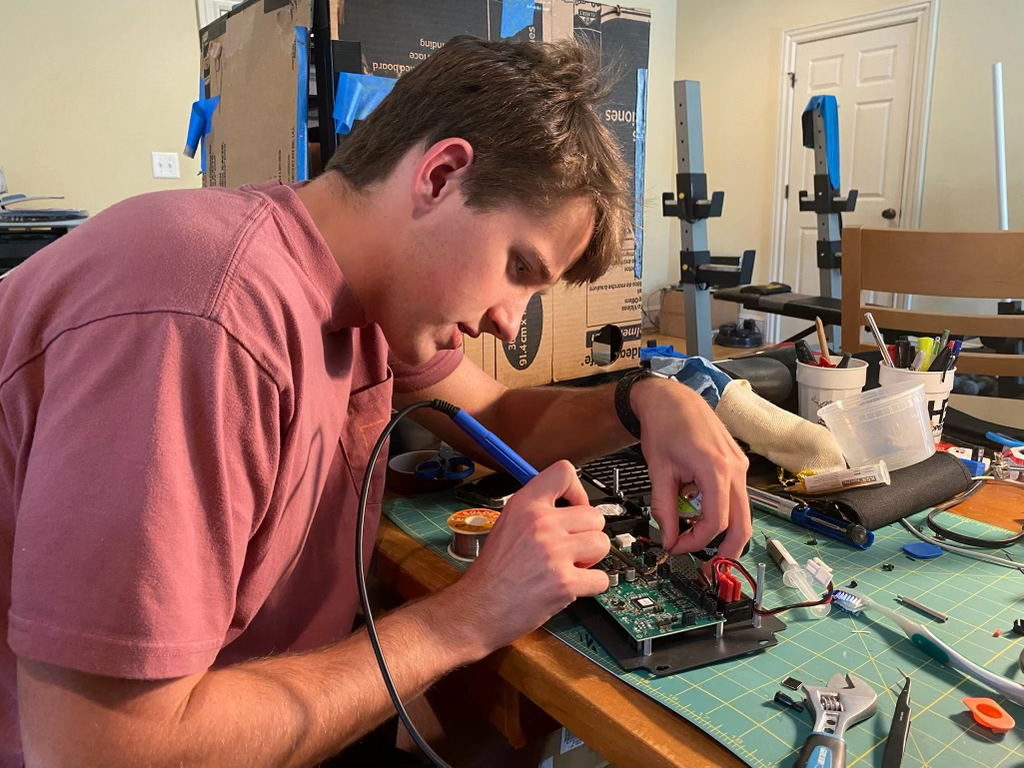

Then, I removed the old chip. I cleaned up the solder pads with a normal soldering iron, and my friend David got a photo of me😀. My hair is pretty messy, as well as the whole room🤣.

I put the new chip on, using plenty of flux.

I made sure to wash off the flux afterwards, using a toothbrush and some isopropyl alcohol.

After reassembly, the Carvey worked! I had given it about a 50-50 chance, since I was unexperienced with hot air soldering and wasn’t 100% sure replacing the driver would fix the issue. Plus, I didn’t want to be too optimistic and end up disappointed at a failure. So in reality I was 80% sure it would work.

That’s it!